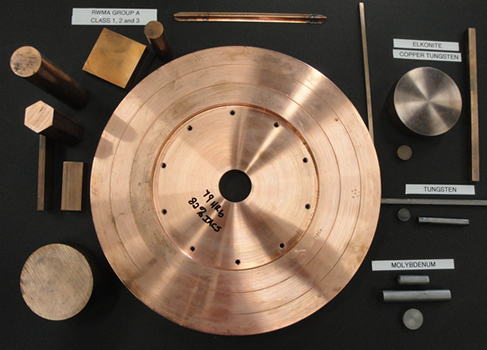

Elkonite 10w3 tungsten copper 75w 25cu is used for electrode and die inserts in most flash and butt welding dies and for projection welding dies where welding pressures and moderate.

10w3 copper tungsten.

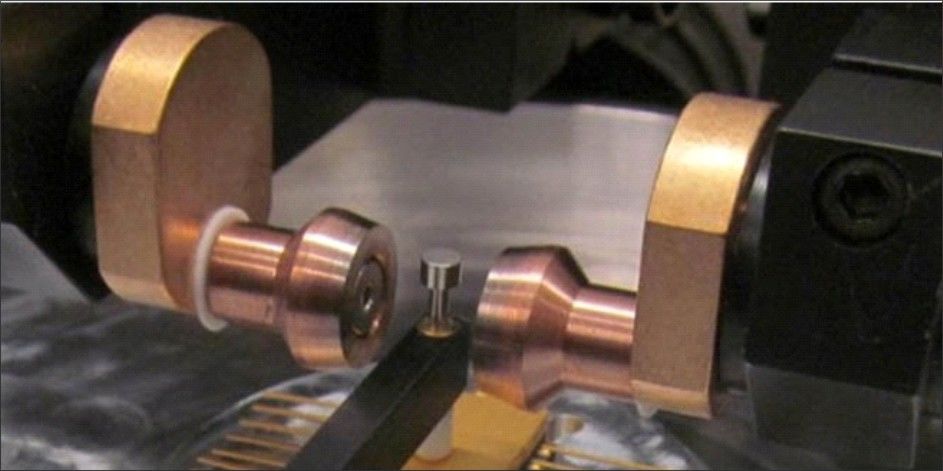

It may also be used as seam welder bearing inserts and facing for electro forming or electro forging such as stainless steel.

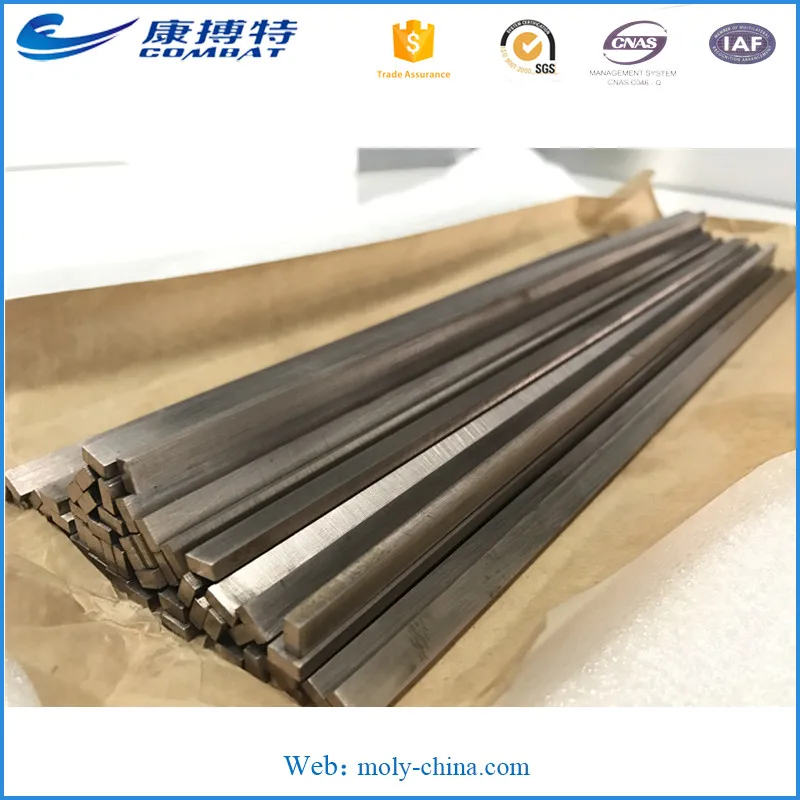

Cuwrod sheet bar for edm spot welding electrode heat sink for the 10w3 30w3 elkonite sparkal tuco.

Heavy duty projection welding electrodes die facings for electro forming and electro forging also facings for upsetting of rivets and studs.

Our company has more than 10 years experience to produce the silver tungsten alloy.

We are iso 9001 certified compliant with all major air and vacuum smelters and will travel to any location in the world to assess sample and validate tungsten materials.

Copper tungsten composite hosopm copper tungsten product has very high density and hardness.

Cross wire welding of copper and brass wires and welding of copper wire braid to brass and bronze terminals are.

Most nut stud welding applications use this alloy brazed on the electrode face.

Most nut stud welding applications use this alloy brazed on the electrode face.

Elkonite copper tungsten is also used successfully as facing on spot welding electrodes where heat balance or mechanical wear resistance is required.

At quest alloys we purchase tungsten in all forms including tungsten carbide elkonite tungsten powder and all heavy metals.

Copper tungsten silver tungsten silver tungsten alloys contain between 25 50 silver and are mainly used for electrical contacts generally heavy duty devices subject to high current.

Copper tungsten class 11 10w3 class 11 a harder material than class 10 is recommended as facing inserts for flash and butt welding dies and general purpose projection welding electrodes.

Elkonite 10w3 tungsten copper 75w 25cu is used for electrode and die inserts in most flash and butt welding dies and for projection welding dies where welding pressures and moderate.

The initial premium cost of elkonite copper tungsten is offset by lower production cost per weld due to long die life and less electrode dressing time.

Mi tech tungsten metals copper tungsten alloys are commonly used in edm electrodes and other electrical and electrical thermal applications.

20 copper and 80 tungsten.

Hosopm copper tungsten product has very high density and hardness.